Safer Handling: ProGMA

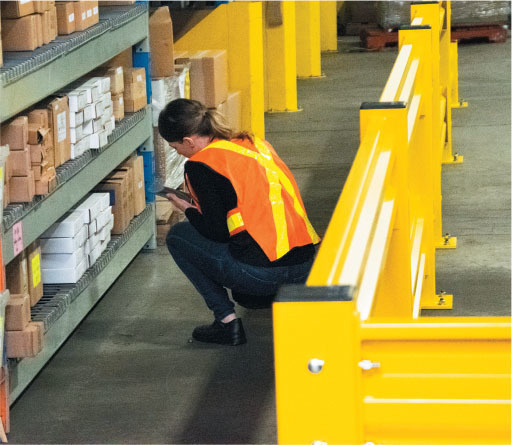

People need to feel safe to be productive, and in industrial environments a crucial component of keeping workers safe is keeping them adequately separated from certain equipment. Fixed protective guarding products, such as safety fences, netting, guardrails and bollards, are the key tools used to ensure manufacturing and distribution facilities are as safe as possible by keeping workers and potentially dangerous equipment away from each other.

People need to feel safe to be productive, and in industrial environments a crucial component of keeping workers safe is keeping them adequately separated from certain equipment. Fixed protective guarding products, such as safety fences, netting, guardrails and bollards, are the key tools used to ensure manufacturing and distribution facilities are as safe as possible by keeping workers and potentially dangerous equipment away from each other.

Members of the Protective Guarding Manufacturers Association (ProGMA), an industry group within MHI, represent the industry’s leading suppliers of fixed protective guarding products designed to protect personnel, equipment, and inventory in industrial facilities. Occasional accidents are likely, but the ProGMA and its members strive to limit the dangers and damages those risks represent.

At its essence, protective guarding is about designing a flow and a guarding system that keeps people separated from equipment and machinery that could hurt them, said Dirk Seis, director of marketing for MHI member Ideal Warehouse Innovations, Inc. However, he said, sensitive, sophisticated equipment also needs guarding.

“In a typical facility, there is expensive machinery and if it is hit by moving equipment, it’s out of service. Some equipment can be worth millions of dollars, so protecting it from incidental impact is very important,” Seis said. “If you think of a warehouse like a roadway, there can be accidents every day. Guarding protects against all of that.”

In that vein, a major development in recent years in the protective guarding field is the emergence of guarding that can absorb multiple impacts without needing to be immediately replaced. In the “old days,” Seis said, steel guarding, which comprises fabricated steel components, was the only type of protective guarding available.

“These days, there are polymer designs, there are flexible designs, there are impactable designs, there are rebounding designs, and they allow multiple impacts in the same spot before repair is necessary,” Seis said. “You’ve got places where impact is more likely in a facility, and in those cases, many companies have chosen to put something in there that’s more forgiving while still protecting the product. It protects what it’s designed to protect, but it bounces back and lives another day versus traditional guarding, which is less costly, but it will typically only take one hit and then needs either significant repair or replacement.”

Seis said the European markets have more ambitiously made the transition to newer guarding that can absorb multiple impacts. The newer guarding is more expensive, he said, but can save money in the long term because of its ability to endure longer than traditional guarding.

“The more companies understand how much longer this newer guarding lasts and perform the ROI calculations, then the more this newer technology will be adopted,” he said.

MHI Solutions Improving Supply Chain Performance

MHI Solutions Improving Supply Chain Performance