Product Spotlight

BY CATHY LANDRY

As e-commerce continues its explosive growth, warehouse operators must evolve and innovate. Capturing a parcel’s dimensional weight in motion during the Scan, Label and Auto Manifest (SLAM) process allows users to reap huge benefits including quality control, cost savings, increased efficiency and greater productivity, experts say.

“An investment in warehouse pack-and-ship automation inclusive of shipment dimensional weight capture is a business accelerator,” said Dan Hanrahan, founder and CEO of MHI member Numina Group. “In simple terms, it allows you to ship more orders in optimal carton sizes to lower your shipping costs.”

As warehousing activities increase with the explosion of e-commerce, more mid-sized and smaller companies are investing in automated warehousing solutions, especially those poised to grow, Hanrahan said. “It’s important to choose the right mix of technologies that will reduce labor and operation costs today and in the future.” Include order cartonization software to preselect the right size carton or padded bag based on the weight, size and shape of the order’s products. Cartonization drives cost savings and efficiency across the entire order fulfillment operation, he explained.

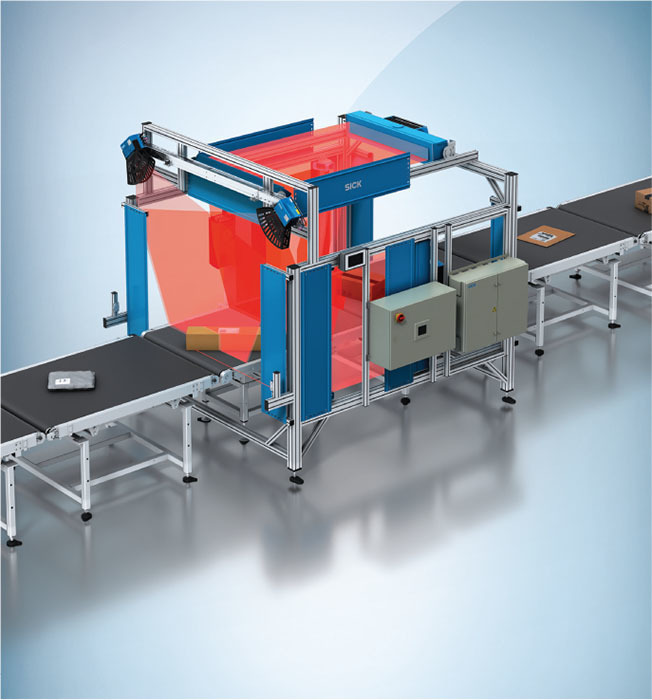

Don DeLash, sales leader in logistics automation for MHI member SICK USA, said dimensional weight is important in all aspects of the warehousing process, particularly for rate shopping on outbound shipments. “Many customers can use different carriers,” he said. “If you can capture volume and weight accurately, you can shop in real time for the best rate.”

Implementing the right dimensioning solutions also produces efficiency gains, DeLash said. “Selecting and verifying the proper package size and packing materials optimizes the process,” he noted. A small item in a larger-thanneeded box requires additional packaging and will take up more space in the truck or plane, DeLash said. “The bigger box and additional packaging both cost money, and, of course, the larger box—even if it weighs the same as a smaller box—will increase shipping costs because it takes up more space,” he explained.

Hanrahan agreed, noting that capturing dimensional weight is “critical to ensuring you are picking and packing into the minimal-sized carton. If [the automated solution]can select and enforce [the items]ship in the minimal-sized package, you can save a lot of money over time.” In the past, SLAM—the final step of the process between packing and outbound sorting—was largely overlooked when warehouse operators were investigating cost savings and productivity improvements.

MHI Solutions Improving Supply Chain Performance

MHI Solutions Improving Supply Chain Performance