CHICAGO‑BASED STARTUP ARVIST AI is redefining warehouse automation with a vision‑based platform that integrates seamlessly into existing infrastructure. Founded with a focus on safety analytics, Arvist has expanded into quality control and compliance, helping customers reduce manual tasks, eliminate barcode scanning and improve operational accuracy—without disrupting their current systems.

CHICAGO‑BASED STARTUP ARVIST AI is redefining warehouse automation with a vision‑based platform that integrates seamlessly into existing infrastructure. Founded with a focus on safety analytics, Arvist has expanded into quality control and compliance, helping customers reduce manual tasks, eliminate barcode scanning and improve operational accuracy—without disrupting their current systems.

The company just closed a $4 million seed round in late 2025, which should allow it to scale, Founder and CEO Nilay Parikh said.

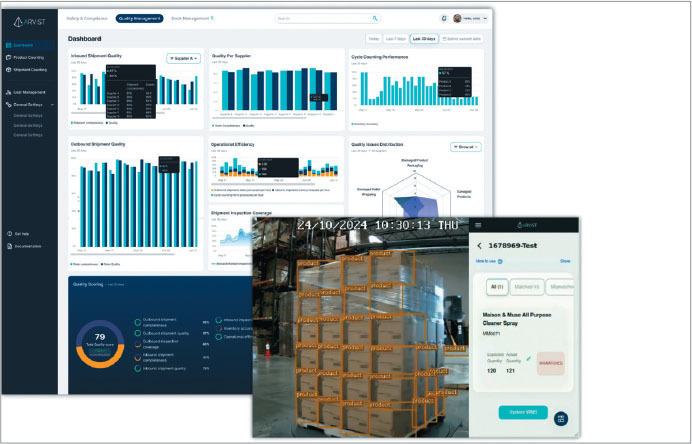

Arvist AI’s dashboard provides a snapshot of inventory and shipment levels, tapping into existing security camera networks and warehouse management systems. Photo provided by Arvist

Arvist uses AI tools to detect damage as pallets leave the warehouse or to ensure compliance. It also can help resolve issues. If a retailer reports receiving the wrong goods, Arvist can find the shipment ID, match it to data and automatically fill out the over, short and damaged (OSD) claim. “We have images of all four sides of the pallet at the time of departure,” Parikh said. “You can say, ‘Talk to your carrier—it’s not our responsibility.’ That entire process is automated and ready for sign‑off.”

The financial impact is substantial. One customer shipping tobacco products faced annual losses of $2–3 million due to rejected shipments. “They had 99% accuracy, but that 1% error rate was costly. We helped them reduce that to 0.5%, saving $1.5 million,” Parikh said.

Another customer saw immediate labor savings by moving two people from quality control to more productive roles. According to Parikh, “watching pallets load all day is mentally taxing—this was a win for efficiency and morale.”

BUILT TO WORK WITH WHAT YOU HAVE

Arvist connects to customers’ existing security camera networks and warehouse management systems, allowing for faster deployment and a shorter learning curve. “Most automation projects fail because they introduce change management,” Parikh said. “We avoid that as much as possible so automation sticks.”

If a facility already has cameras, Arvist helps reposition them for optimal coverage. If not, the team works with security vendors to add a few low‑cost units. “It’s low‑risk from an IT perspective,” Parikh said. “We don’t disrupt the security platform, and we can run without warehouse management system (WMS) integration—though that limits functionality.”

Though Arvist began as a safety analytics company, safety is now a complementary layer to its quality control platform. “Safety is a harder sell because the return on investment (ROI) is abstract,” Parikh said. “If you haven’t had an accident or Occupational Safety and Health Administration (OSHA) fine, it’s hard to quantify the savings. But when we bundle safety with quality, it becomes a strong value proposition.”

Features include detection of personal protective equipment, forklift near‑misses and behavioral alerts, like distracted employees using cell phones or improperly stacked pallets. “Near misses are critical; they’re precursors to accidents,” Parikh said. “We help customers proactively change behaviors before something goes wrong.”

Arvist’s models currently focus on boxed products, with accuracy rates between 90–95% during initial deployment. “We do a four‑ to six‑week onboarding where customers test and train the system. That’s when we push accuracy up to 98%,” Parikh said. Models for awkward‑shaped items were in development and expected to launch in late 2025.

Long term, Arvist aims to eliminate barcode scanning. “Fifty percent or more of manual tasks in a warehouse involve scanning and data entry,” Parikh said. “If we can automate that with visual proof throughout the facility, it’s a significant value add.”

MHI Solutions Improving Supply Chain Performance

MHI Solutions Improving Supply Chain Performance