BY DR. FABIO SGARBOSSA, PROFESSOR OF INDUSTRIAL LOGISTICS, DEPARTMENT OF MECHANICAL AND INDUSTRIAL ENGINEERING, NORWEGIAN UNIVERSITY OF SCIENCE AND TECHNOLOGY (NTNU)

Efficient utilization of material handling equipment (MHE) significantly impacts the productivity, profitability and flexibility of production systems. For instance, machine performance could be impacted when a forklift driver is unavailable, or unit loads in the unloading station are still waiting to be transported to the next production phase. In modern production systems, cloud technologies are considered cutting-edge, with cloud manufacturing impacting the management of production through the ability to share real-time information about product status and all production services. While cloud technologies have been widely analyzed and discussed on a shop-floor level connecting machines, material handling systems have not received as much attention.

The typical structure of material handling systems is a combination of different equipment with varying levels of automation, including manual and mechanized systems where humans still play a critical decision-making role. Automated solutions like Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) for material transportation and various evolutions of Automated Storage and Retrieval Systems (AS/RS) for material storage have been introduced in recent years, but these systems are characterized by central control architecture. Therefore, a multilevel hierarchical control system is required to coordinate the different subsystems and enable products to move efficiently within the production systems.

Recently, the availability of Industry 4.0 technologies such as indoor positioning technologies, Internet of Things, motion tracking and control and cloud computing make MHE a viable solution to increase productivity, profitability and flexibility of production systems.

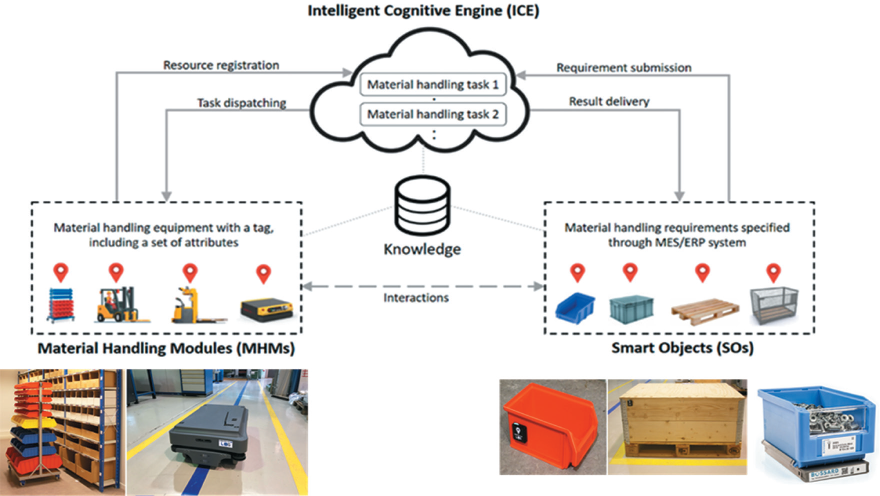

In 2020, to extend the definition of cloud manufacturing to cover handling activities, researchers in the Logistics 4.0 Laboratory at the Norwegian University of Science and Technology have introduced and developed a new kind of paradigm called the Cloud Material Handling System (CMHS). (Figure 1)

The concept can be compared to transportation service providers and platforms like Uber, Lyft and others. In this case, the unit loads or Smart Objects (SOs) requiring a specific service from the system are the “consumers,” while the MHE with different capabilities are the “cars” and “drivers,” called Material Handling Modules (MHMs). The Intelligent Cognitive Engine (ICE) is the core of the CMHS platform, which dynamically schedules and assigns handling requests to the available MHE resources using Artificial Intelligence (AI).

The implementation of indoor positioning technologies and sharing of the attributes/functions and positions of SOs and MHMs enable new decision-making processes for scheduling and control of all components in the system. The CMHS has the potential to reduce the complexity of a multilevel hierarchical control system and increase the overall productivity, profitability and flexibility of the production system. The CMHS has been primarily developed for applications within a factory and production system or warehouse/distribution centers but can also be extended to a multi-factory environment where logistics activities also involve external transportations.

The CMHS bridges the gap between conventional material handling systems and fully automated ones, providing automation capabilities for all MHMs, including human-operated ones. Manual solutions often rely on conventional dispatching methods with low flexibility, but the CMHS enables increased freedom of movement for all MHMs, regardless of layout configuration and type of material flows.

Click here to read the full article.

ISTOCK.COM/JUST_SUPER

MHI Solutions Improving Supply Chain Performance

MHI Solutions Improving Supply Chain Performance