Feature

The climate impact from your company’s direct operations is likely a fraction of the greenhouse gas emissions produced throughout your corporate value chain, including those generated by suppliers of the goods and services you buy and by customers who use the products you sell. That’s why measuring and mitigating so-called Scope 3 emissions is rapidly emerging as an urgent business priority on the path to a net-zero global economy. Here’s what you need to know about Scope 3 and how to make what seems like a daunting task more manageable.

When Mitsubishi Electric Corporation, parent company of MHI member Mitsubishi Electric Automation, issued its environmental report for FY 2022, the numbers showed that nearly all of the greenhouse gas (GHG) emissions it produced—99.3%—came from outside its own operations.

Almost all of Mitsubishi Electric’s emissions could be traced to two sources—goods and services it purchased from suppliers, and emissions generated by customer use of the products it sold. Product use alone accounted for 92.2% of total emissions.

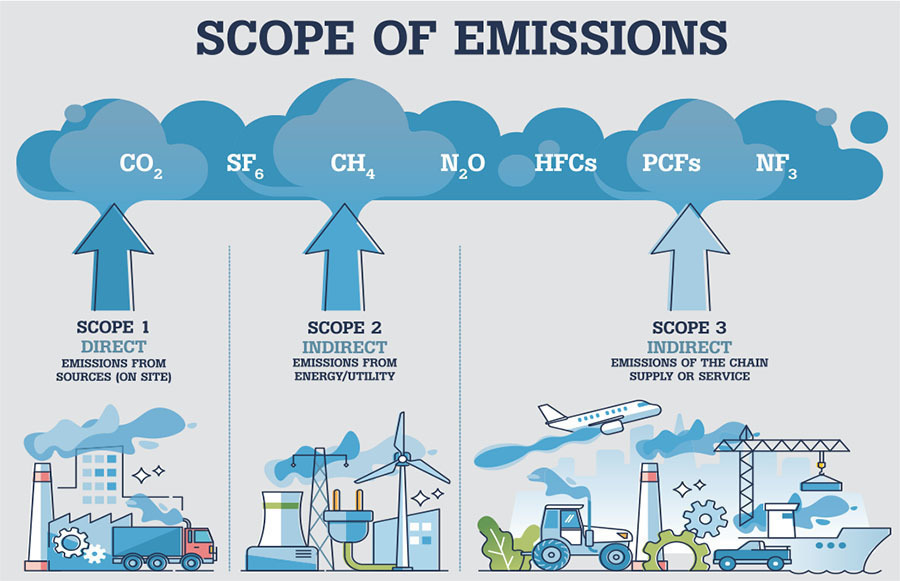

For most companies, in fact, the climate impact of what takes place within the four walls of the enterprise is dwarfed by those generated throughout the corporate value chain—Scope 3 emissions as defined by the GHG Protocol, the standard for measuring and reporting emissions now used by companies worldwide.

Supply chain emissions are on average 11.4 times higher than operational emissions, which include direct emissions from operations, classified as Scope 1, and indirect emissions—Scope 2—associated with purchased electricity, steam, heating and cooling, according to the 2021 Supply Chain Report from emissions disclosure platform CDP.

That’s more than double previous estimates, and emerging awareness of the outsize impact of value chain emissions on a company’s carbon footprint is why measuring and mitigating Scope 3 emissions is rapidly becoming a critical priority in the race to meet net-zero emissions targets by 2050 or sooner.

“To understand the environmental impact of a company’s economic activities, it is not enough to look at its direct emissions and risks,” CDP said in its report. “The entire value chain must be engaged to evaluate and improve its performance.”

It’s not happening yet. A global survey by Boston Consulting Group found 66% of respondents were not reporting any of their Scope 3 emissions, and only 9% claimed to measure their total emissions comprehensively.

Turning up the heat

If you haven’t heard of Scope 3, you’re not alone. Jen Bennett, technical director for sustainability in the office of the CTO at Google, says only a handful of experts in most companies understand the meaning and significance of the term.

“If you were to ask the average person in an organization about Scope 3, I guarantee you even in the best of organizations, you will struggle to have everyone understand with any level of detail what that means,” Bennett told listeners on a recent webcast organized by GreenBiz and sponsored by the Environmental Defense Fund (EDF).

Expect that to change as customers, regulators, investors and other stakeholders turn up the heat on businesses to accurately measure and report Scope 3 emissions—and then take decisive action to squeeze them out. The challenge will take an all-hands effort from CEO and board on down. Consider:

- The Securities and Exchange Commission (SEC) is weighing a proposed climate disclosure rule that would require companies of a certain size to begin reporting Scope 3 emissions.

- 154 countries have submitted plans to reduce emissions as part of the Paris Agreement and Glasgow Climate Pact, and business and industry will feel increasing pressure to do their part.

- The Science-Based Target initiative (SBTi) launched a new Net Zero Standard in 2021 that calls for a full value-chain approach and requires companies to meet interim Scope 3 emissions goals.

- Scrutiny by media, investors and consumers will increase with the emergence of better data, so companies may be judged harshly if actual results fall short of announced climate commitments.

- A survey of major buyers participating in CDP’s Supply Chain Program found that 73% expect to “deselect” suppliers based on inadequate progress toward emissions-reduction goals.

The growing Scope 3 focus is reshaping relationships throughout the value chain as companies engage suppliers to share their emissions reduction goals. Downstream, it’s driving deeper collaboration with customers to help companies find new efficiencies in how their products are designed and used.

Tackling Scope 3 a ‘daunting task’

Scope 3—also known as the Corporate Value Chain Standard—became the last category of greenhouse gas emissions to be added to the GHG Protocol in 2011, a full decade after the Protocol was created with the establishment of the Scope 1 standard in 2001 and seven years after Scope 2 was defined.

The fact that most companies are just beginning to look at Scope 3 reflects the relative lack of urgency around addressing climate change until recently, but it’s also a function of the complexity of measuring Scope 3 emissions, a task Elizabeth Sturcken, managing director for the EDF, calls “daunting.”

One reason is that reliable Scope 3 emissions data remains elusive and hard to measure, and unlike Scope 1 and 2 emissions related to your direct operations, the data belongs to a supplier or another partner in your value chain. Scope 3 is also challenging because it covers 15 distinct sources of emissions (see sidebar), from purchased goods and services to emissions generated by the use and end-of-life disposal of their products.

In between are emissions related to transportation and distribution of products from supplier to company and from company to customers, waste generated by operations, business travel, leased assets, franchise operations and even the investment choices your finance team makes from day to day.

The silver lining: Quantifying Scope 3 emissions should get easier over time as suppliers and other value-chain partners improve measurement and reporting of their own Scope 1 and 2 emissions. That’s because of what Kevin Rabinovitch, global vice president of sustainability and chief climate officer for Mars Inc., calls “the genius of the Scope 1-2-3 logic” enshrined in the GHG Protocol.

“Everything is somebody’s Scope 1 and 2, so all of your Scope 3 is somebody else’s Scope 1 and 2,” Rabinovitch told listeners on the GreenBiz webcast. “In that sense you’ve got a complete accounting system.”

Kevin Webb, senior director of sustainability and social impact for the Mitsubishi Electric Group companies in the Americas, agrees accounting for Scope 3 emissions will become less onerous as value-chain partners begin to provide more accurate and comprehensive data on emissions from their direct operations.

“The key to successful Scope 3 reporting is being diligent about reporting on your own Scope 1 and 2 emissions,” Webb said. “Providing this data publicly reduces the need for surveying and estimating, which provides a more accurate accounting to others in the value chain.”

VECTORMINE/SHUTTERSTOCK.COM

VECTORMINE/SHUTTERSTOCK.COMFocus on the big buckets

In the meantime, companies further along the carbon accounting maturity curve have plenty of advice for those just getting started. One common-sense approach they recommend: Identify the largest sources of Scope 3 emissions using procurement analysis or a hybrid of spend data and supplier-provided information and tackle those first.

Instead of trying to measure emissions from all of your suppliers, which for large companies number in the hundreds of thousands, identify the biggest ones and partner with them first. Walmart, which launched an initiative in 2017 to cut GHG emissions by 1 billion metric tons by 2030, is a case in point. The retail behemoth has more than 100,000 suppliers worldwide, but for its Project Gigaton it is focusing on 2,500 suppliers that account for 70% of the company’s U.S. product net sales and asking them to report their emissions. As of 2021, the company had reduced or avoided 547 million metric tons of emissions.

For companies like Mitsubishi Electric, which makes electric motors, variable frequency drives (VFDs) and other products that consume energy, the Scope 3 challenge will be more focused on efforts to shrink the carbon footprint of its products and work with customers to improve efficiencies in how they are used. Since 2001, through improved product performance, Mitsubishi Electric Group has reduced the carbon emissions from product usage by 36% across 98 product groups.

“By focusing on increased performance, it helps drive down other companies’ Scope 1, 2 and 3 emissions,” Webb said. “As they purchase the products and begin to implement them, it’s helping to work toward a net zero future for our customers and society.”

Helping customers realize new energy efficiencies is another way Mitsubishi Electric is reducing its Scope 3 emissions. The company helped Bastian Solutions design a stacker crane capable of lifting 12,000-pound loads using VFDs and servo systems supplied by Mitsubishi Electric Automation. The system helps control load sway, improve the crane’s efficiency and reduce motor speeds, thus cutting overall energy use.

Edgar Becerra, senior manager of environmental sustainability for Mitsubishi Electric Group companies in the Americas region, describes the company’s journey to net zero emissions as an “iterative process” that began with a focus on Scope 1 and 2—replacing lighting with LED fixtures, installing solar panels on the corporate headquarters and using more recycled material in its products—and then digging into the key Scope 3 issues such as reducing emissions from suppliers and boosting energy efficiency in product use.

But while focusing on the big buckets of opportunity, the company has also found ways to make inroads into eliminating other sources of Scope 3 emissions. At Mitsubishi Electric Automation, CEO Scott Summerville’s team saw an opportunity to cut emissions related to waste generated in operations—Category 5 of Scope 3—by eliminating bubble wrap used as packing material and replacing it with shredded cardboard recycled from the boxes of incoming shipments from suppliers.

MHI Solutions Improving Supply Chain Performance

MHI Solutions Improving Supply Chain Performance